SGCI News

[LAGOS] Nigerian researchers have created a hybrid gas- and solar-powered device that automates the production of the Nigerian staple garri, improving efficiency and reducing health risks for producers. Garri, a…

- Gas- and solar-powered machine promises to make garri production safer

- ‘Jolly Frier’ targets health risks faced by producers – mostly women and girls

- Researchers say the machine is ready for commercialisation

[LAGOS] Nigerian researchers have created a hybrid gas- and solar-powered device that automates the production of the Nigerian staple garri, improving efficiency and reducing health risks for producers.

Garri, a granular flour made from cassava, is usually produced using a wood burning stove. This puts those who make it – mostly women and girls – at risk of respiratory and heart diseases.

The World Health Organization links around 3.2 million deaths per year globally to household air pollution from dirty stoves and fuels such as firewood, with women in low- and middle-income countries bearing the highest burden.

“One of our major targets is to stop exposure to smoke by substituting the use of firewood with clean and renewable energy,” says Cecilia Oluwamodupe, the lead researcher from Olusegun Agagu University of Science and Technology, in Nigeria’s Ondo state.

She says the machine, named the Jolly Frier, will ensure the safety of garri producers. “The health hazards will be reduced or removed totally,” she adds.

Oluwamodupe explains that her team wanted to help tackle food insecurity in Nigeria using a locally-made product.

Garri, which is widely consumed in Nigeria and other West African countries, is made by fermenting ground cassava, removing excess water, then sieving and frying it to achieve its final form.

The Jolly Frier has three key parts: a drum that stirs the garrito prevent lumps; a control panel that manages temperature and pressure, and a gas-powered heating chamber.

It also has a solar-powered rotor and an automatic shutoff system that reduces the need for constant monitoring.

Once the garri is properly fried, the system automatically turns itself off, allowing the final product to be collected safely and efficiently.

Oluwamodupe says the new technology will make processing garri a lot easier for the women and girls who mostly do it.

“Based on our market validation, 90 per cent of garri producers are women and youths,” she explains.

“In fact, in all our validation in southern Nigeria, we only found one or two men among hundreds of women and young girls frying garri.”

Funded by the Science Granting Councils Initiative (SGCI) in collaboration with Nigeria’s Tertiary Education Trust Fund (TETFund), the Jolly Frier was developed by a five-member research team from research institutions across Nigeria.

It was one of four prototypes developed by the team through the Research for Impact (R4i) Initiative, a partnership between TETFund and Innov8 Hub, an Abuja-based innovation centre.

“We got a grant of US$250,000 from SGCI to implement four projects that involve research and innovation, including the Jolly Frier,” says Hadiza Ismail, a deputy director at TETFund and the lead project coordinator for SGCI in Nigeria.

“The SGCI has also built our capacity in terms of research management,” Ismail adds, citing workshops run by the SGCI.

The project started in July 2024 and is slated for completion by June 2025.

Ready for market

A prototype has already been developed and reviewed, with final testing underway, and intellectual property rights have been secured, according to the researchers.

“We are now preparing for mass production and commercialisation,” adds Oluwamodupe.

She says there has been substantial interest from garri producers, eager to integrate the technology into their operations.

“This innovation will increase production, improve product quality, and eliminate health hazards associated with traditional processing methods,” says Oluwamodupe.

She adds: “Although the initial cost may be high, a community can collectively invest in a unit and entrepreneurs can also purchase multiple machines to establish garri frying hubs.”

Matthew Oluwamukomi, a professor of food science and technology at the Federal University of Technology, Akure, is optimistic that the innovation can enhance the capacity of rural women to produce garri on a large scale.

“[Garri-making] is a lucrative business and this technology will no doubt remove the drudgery associated with its production,” he says. “We have no choice but to embrace technology to address food insecurity. We have to invest in it to make food easy to produce.”

This article was written by: Afeez Bolaji

Related News

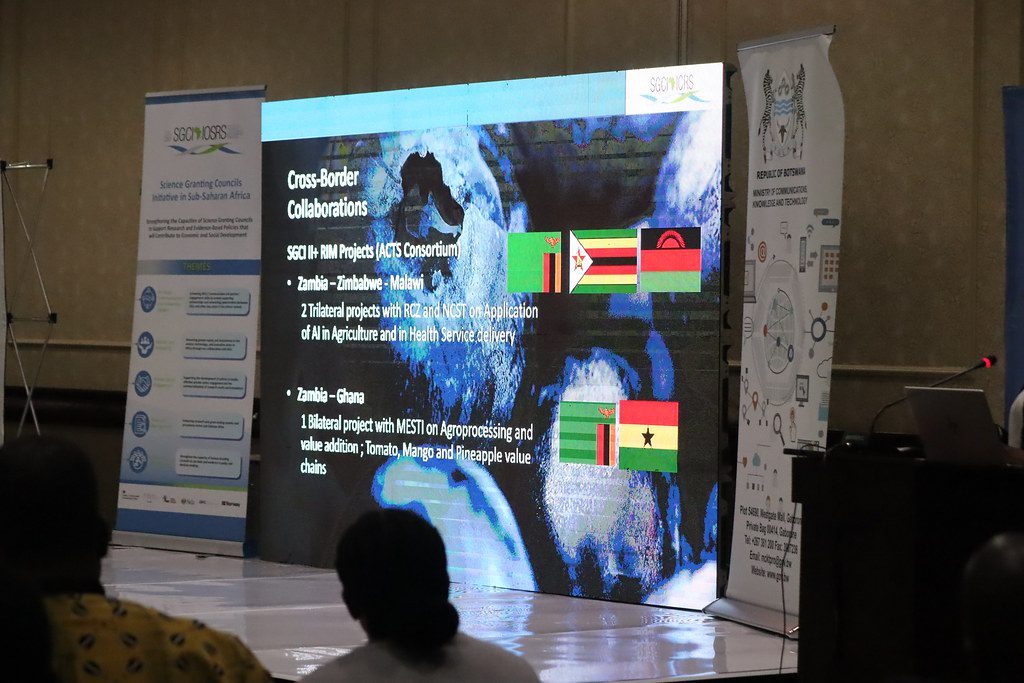

How Zambia’s science council is funding research that matters

When Zambia’s National Science and Technology Council (NSTC) was established in 1997, its founding vision was to harness science, technology, and innovation to improve the lives of ordinary Zambians. More than two decades later, that vision is increasingly taking shape through a growing portfolio of…

Voices of SGCI: Council leaders on the direction and ambition of SGCI 3

At the African Union’s Science, Technology and Innovation Week in Addis Ababa, earlier this month, leaders of science granting councils reflected on what SGCI Phase 3 represents for Africa’s science and innovation systems. From ownership and alignment to stewardship and sustainability, here are their voices…

Building Africa’s science future: inside the SGCI alliance

As Phase 3 of the Science Granting Councils Initiative launches on the margins of the African Union Summit in Addis Ababa last week, the SGCI Alliance Chair explains why this moment marks a decisive turning point for African science. Cephas Adjei Mensah describes what is…

SGCI funded projects

Rwanda’s integrated approach to sustainable agriculture and nutrition

Project Titles & Institution Areas of Research Number of Projects being funded Project Duration Grant Amount In-Kind Distribution Council Collaboration with other councils